The Basics: Sewing Machine Needles

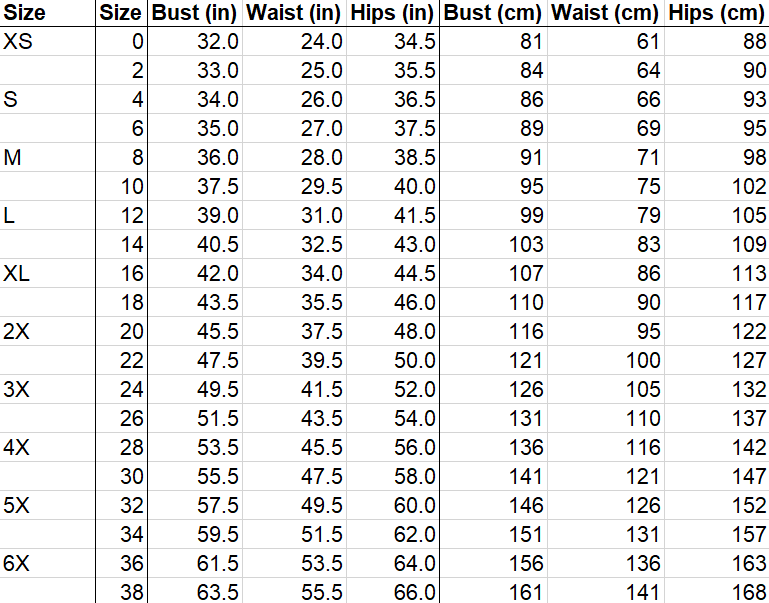

Whether you’re a sewing beginner or seasoned pro, choosing the right sewing machine needle for your project can be difficult, especially since the number of different types of needles is quite overwhelming. But this guide will help you figure out exactly which machine needle is right for your sewing, quilting, or embroidery project, as well as why. Bonus information includes how often you REALLY need to change the needle, and it’s not as often as you might think. A quick-reference chart is provided at the end with a summary of all the information.

Each type of needle is shaped in a specific way that enables it to do its job. Needles with sharper points pierce the threads of the fabric, while more rounded points move between the threads. Sharp points are helpful in keeping the thread from breaking or shredding. Rounded points help to avoid snagging the fabric, which is a bigger issue with some types of fabrics over others. Needles are sharp and/or round depending on which type of fabric they’re made for. There are also differences in length, eye size, scarf, and strength to customize them for their specific purposes. In this post, we’ll talk about basic and specialty needles, what you should use them for, and why.

Starting with the basics, you have your three all-purpose machine needles: Universal, Ballpoint, and Sharp/Microtex. Universal needles are, as the name suggests, the ultimate general needle. They can be used for wovens and knits since their point is slightly rounded to pass between knit threads but sharp enough to pierce the threads of woven fabrics. They come in all types of sizes, and their versatility makes them ideal for beginners. Next are the Ballpoint needles. These are used for knits, and their rounded tip is perfect for passing in between the threads in knit fabrics. They won’t damage spandex, interlocks, and other knits that snag and run easily. The third type of needle is Sharp/Microtex. These are narrow with a sharp point to pierce the threads of woven fabrics. These needles enable perfectly straight stitching, which also makes them ideal for heirloom stitching, topstitching, pintucks, and edge stitching.

The rest of the types of needles are specialty needles, most with self-explanatory names. First are the stretch needles. These are designed for lightweight knits, extremely stretchy fabrics, and elastic; for example, if you were sewing swimwear, you would use one of these. Stretch needles have a deep scarf so the bobbin hook gets closer to the needle eye. This prevents skipped stitches on fine, lightweight knit fabrics. Self-threading needles are helpful when you struggle with threading the needle on your own. It has the same point shape as a universal needle but works best with woven fabrics because it may snag threads on your knits. Metallic needles are specially designed to sew with metallic thread. They feature a large eye, a sharp point, and a large-groove scarf to protect the thread and prevent skipped stitches.

Denim needles are for, you guessed it, denim! They can also be used for heavy woven fabrics like canvas and duck, or for stitching through multiple layers. They have a strong shaft and an extra sharp point. Leather needles are for leather as well as suede, vinyl, heavy faux suede and leather, and other thick nonwoven materials. They have a wedge-shaped point that penetrates the material without tearing it. With leather needles, it’s important to stitch accurately because the needle leaves a large, permanent hole. You should also tie thread ends instead of backstitching to prevent perforating the surface of the material.

There are quite a few more needle types that are specific to sewing techniques. There are machine embroidery, quilting, and topstitching needles, which all do what their names suggest. Twin and triple needles are for double and triple topstitching, respectively. Overlock needles are for sergers, spring needles are used in free-motion embroidery or quilting, and wing/hemstitch needles are for decorative and heirloom stitching.

Some people say that needles should be changed after every project, but depending on how big the projects are, after every 3-4 projects should be just fine. If it’s punching through the fabric -- meaning you can hear it going through the fabric -- damaging the fibers, pulling the threads, or snagging the fabric as it goes down, it’s time to change the needle. Some of these may be an issue with the type of needle you’re using, that is that it’s the wrong needle for your project. Or it might just be that it’s the needle’s time to go. Try replacing the needle with the same type and try sewing some scraps of the same type of material. If the issue persists, you know that the needle type isn’t right for the job, and you can refer to the notes above to help you find which one will work. This goes without saying, but if a needle breaks, it needs to be replaced.

As I said, it can get a bit overwhelming with all these options, but with this guide, you’ll always have a quick reference guide to refer to whenever you need it! Happy sewing.

Written by Miranda Marnik-Said

Resources:

https://www.craftsy.com/sewing/article/how-to-choose-sewing-needles/

http://www.sewing.org/files/guidelines/22_115_sewing_machine_needle_charts.pdf